Aflatoxin B is a common mycotoxin in agricultural products. After contaminating peanuts, corn, wheat and other crops, it not only affects the quality of agricultural products, but also may enter the human body through the food chain. Long-term intake will increase health risks. Therefore, establishing a whole-process prevention and control system from harvesting, warehousing to processing is the key to ensuring the safety of agricultural products.

Harvesting Stage: Reduce the risk of pollution from the source

Before harvesting, it is necessary to strengthen field management, reasonably rotate crops to reduce the residue of mold spores in the soil, scientifically fertilize to avoid excessive nitrogen fertilizer causing crops to grow and reduce the probability of mildew. Harvesting timing should be carried out in time when the maturity of the crops is suitable to avoid overripe or premature picking causing mildew in the field; during the harvesting process, it is necessary to handle it with care to reduce mechanical damage, because the damaged parts are easy to become a hotbed for mold breeding. Immediately after harvesting, drying treatment is required to control the moisture content of agricultural products within a safe range (such as peanuts, corn, etc. 13%) to inhibit the growth and reproduction of Aspergillus flavus and lay the foundation for subsequent links.storage stage: create a suitable environment to inhibit the growth of mold

The storage environment needs to strictly control the temperature and humidity, keep dry and ventilated, and the temperature is recommended to be controlled at 20-25 ° C and the relative humidity is 65%. Avoid high temperature and high humidity environment to provide breeding conditions Different types of agricultural products need to be classified and stored, especially high-moisture and low-moisture products should be separated to prevent cross-contamination; regularly check the storage environment, clean up the scattered agricultural residues in time, avoid the secondary pollution caused by insects, and use physical insect prevention measures when necessary to reduce the promotion of insect wounds on molds.processing stage: refined treatment to reduce toxin residues

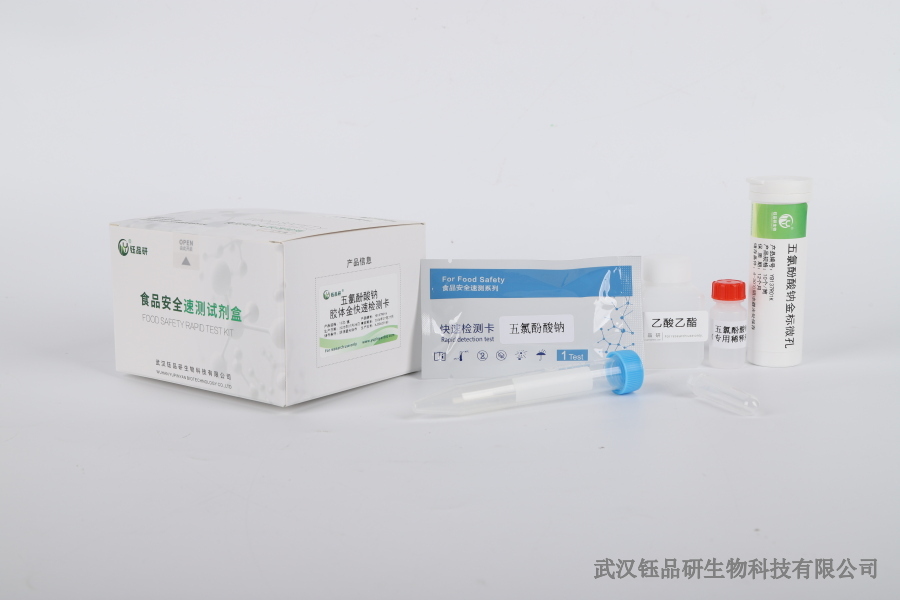

Before processing, it is necessary to remove obvious mildew grains and impurities through screening, stone removal, magnetic separation and other processes to reduce the initial content of toxins; process parameters can be optimized, such as low temperature baking, moderate sterilization and other methods to inhibit mold activity, but it is necessary to pay attention to aflatoxin B High temperature resistance, heat treatment alone is difficult to completely eliminate, so after processing, it is necessary to cooperate with professional testing methods. Processed products should be sealed and packaged in time and stored in a low temperature and dry environment to reduce contact with the external environment and further reduce the risk of toxin contamination.The whole process prevention and control is the core of reducing the risk of aflatoxin B in agricultural products. Every ring needs to be paid attention to from the source control of harvest to the end point detection of processing. The food safety rapid detection reagent produced by Wuhan Yupinyan Bio can quickly and accurately detect the content of aflatoxin B in agricultural products, providing a scientific basis for quality control in all links and helping to ensure the safety of the whole process.