Aflatoxin B is a highly toxic and carcinogenic mycotoxin. Long-term ingestion of contaminated vegetable oils may cause serious harm to human health, such as inducing diseases such as liver cancer. Therefore, the detection and control of aflatoxin B in vegetable oils has always been the focus of food safety supervision. In actual production, enterprises of different sizes have significant differences in raw material procurement, production processing, quality control and other links, which directly affects the risk probability of aflatoxin B exceeding the standard.

For small workshops, due to the small production scale, there is often a lack of standardized processes in raw material procurement, storage, processing and other links. Some small workshops may purchase oils from informal channels. If these raw materials have high environmental humidity and improper temperature control during storage, it is easy to breed aflatoxin B. In addition, small workshops usually lack professional detoxification processes and equipment, making it difficult to effectively remove toxin residues in oils. At the same time, some small workshops may use outdated equipment or simplify production steps in pursuit of low cost, further increasing the possibility of aflatoxin B exceeding the standard. Therefore, from the perspective of the overall production chain, the probability of aflatoxin B exceeding the standard in vegetable oils produced by small workshops is relatively high.

Large-scale enterprises reduce risks by establishing a sound quality control system. Regular large-scale enterprises will strictly screen oil suppliers in the raw material procurement process, and give priority to regular production areas that have passed quality certification. In the storage process, standardized storage conditions are adopted to inhibit the growth of mold through measures such as temperature control and humidity control. In the production and processing process, advanced impurity removal and refining processes are introduced to effectively reduce toxin residues. Before the finished product leaves the factory, it will also use multiple testing processes to ensure that the content of aflatoxin B meets national standards. For example, large-scale enterprises usually have complete laboratory testing capabilities, sampling and testing each batch of products to control product safety from the source. Therefore, the probability of aflatoxin B in vegetable oils produced by large-scale enterprises is usually lower than that of small workshops.

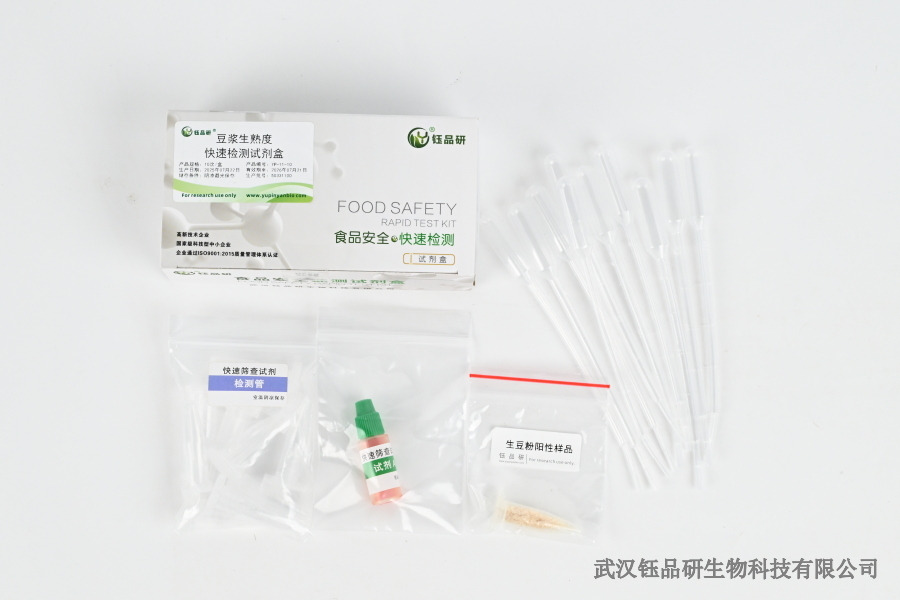

Regardless of the size of an enterprise, fast and accurate detection methods are the key to ensuring the safety of vegetable oils. Wuhan Yupinyan Bio focuses on the field of food safety rapid detection. The aflatoxin B rapid detection reagent developed by it can complete the detection in a short time, helping enterprises and regulatory authorities to detect risks in a timely manner. The reagent is easy to operate and does not require complex equipment. It is suitable for a variety of scenarios such as small workshops and enterprise laboratories. It provides strong support for the safety supervision of the entire chain of edible oil production. Choosing reliable testing products can not only ensure the "safety on the tip of the tongue" of consumers, but also promote the standardized development of the entire edible oil industry.

To sum up, there are differences in risk management and control capabilities between small workshops and large-scale enterprises in the production process of vegetable oil. Large-scale enterprises rely on standardized processes and strict quality control to significantly reduce the probability of aflatoxin B exceeding the standard. However, regardless of the size of the enterprise, attaching importance to raw material safety and strengthening the construction of detection capabilities are the core of ensuring the quality of edible oil. Wuhan Yupinyan Bio will continue to develop efficient detection technology to help the industry build a more complete food safety defense line.