With the rapid development of the precast vegetable industry, this kind of convenience food is deeply loved by consumers because of its deliciousness and convenience. However, in recent years, some products have been exposed to the problem of excessive additives, among which sodium dehydroacetate is a commonly used preservative, and its content compliance has become a key indicator affecting food safety. Wuhan Yupinyan Bio, as an enterprise focusing on the research and development of rapid food safety detection reagents, has sorted out a complete solution from raw material pre-inspection to finished product verification for the risk of sodium dehydroacetate exceeding the standard in the production of precast vegetables.

Risk of excessive additives in precast vegetables: Application and supervision of sodium dehydroacetate

Sodium dehydroacetate has high antiseptic effect and can inhibit the growth of microorganisms such as mold and yeast. It is widely used to extend the shelf life of products in the production of precast vegetables. However, excessive addition will exceed the national standards (such as GB 2760-2014 "National Food Safety Standards, Food Additive Use Standards" stipulated maximum usage), may pose a potential threat to human health. Some enterprises due to the lack of strict control of raw materials, the production process of adding quantity measurement deviation and other issues, resulting in finished product dehydroacetate sodium exceeding the standard, it is urgent to achieve risk prevention and control through scientific testing means.

raw material pre-inspection: control the risk of dehydroacetate sodium addition from the source

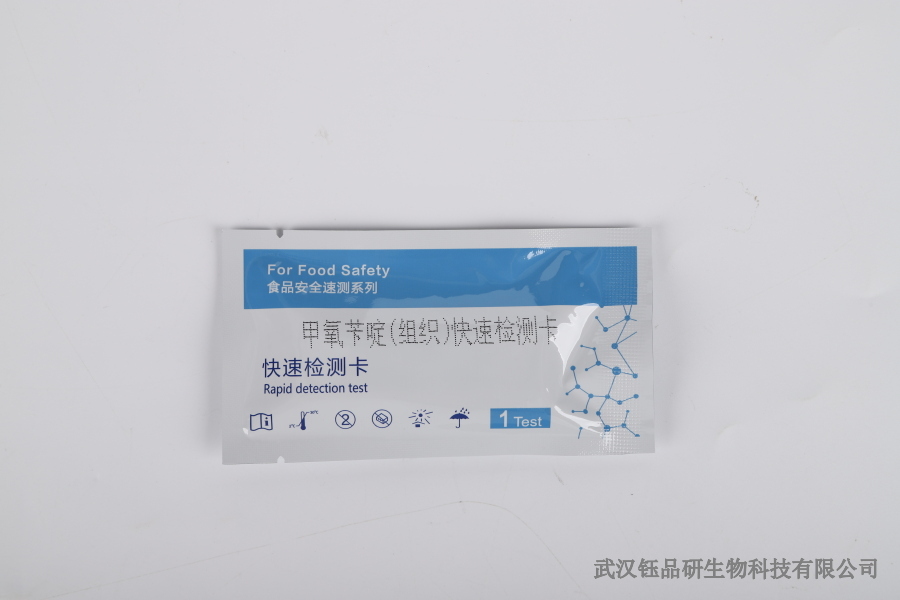

raw materials are the first checkpoint to determine the safety of finished products. In the production of prefabricated dishes, seasoning sauces, sauce packs and other premixes are often used as the main source of dehydroacetate sodium. If the content of the raw materials themselves exceeds the standard, even if the amount added in subsequent production is reasonable, it may lead to the finished product exceeding the standard. Wuhan Yupinyan Bio's food safety rapid detection reagent can help enterprises quickly screen the content of sodium dehydroacetate in the procurement of raw materials. Just take a small amount of raw material samples, through simple pretreatment (such as dilution, filtration), add supporting detection reagents, you can observe the color rendering results within 10-20 minutes, quickly judge whether the raw materials are qualified, avoid unqualified raw materials from entering the production line, and reduce the risk of finished products from the source.

Finished product verification: Accurate detection scheme for the content of sodium dehydroacetate in finished products

After the finished product is produced, the verification of the content of sodium dehydroacetate is a key link to ensure food safety. Wuhan Yupinyan Bio's rapid detection reagent is suitable for on-site testing of prefabricated vegetable products (such as conditioned meat products, quick-frozen vegetables, etc.), without relying on professional laboratory equipment. During testing, take an appropriate amount of samples after simple processing, add reagents according to the instructions, and judge whether the content is within the safe range through color reaction. Compared with traditional testing methods, this scheme has the characteristics of simple operation, intuitive results and fast detection speed, which can help enterprises detect problems exceeding standards in time, avoid large-scale recalls caused by batch problems, and ensure the safety of consumers' tables.

The healthy development of the prefabricated vegetable industry is inseparable from the whole process of food safety control. Sodium dehydroacetate, as a typical representative of additives, has a particularly urgent need for testing. With years of technical accumulation, Wuhan Yupinyan Bio provides enterprises with an integrated solution from raw material pre-inspection to finished product verification. With efficient and accurate testing reagents, it helps enterprises build a strong food safety defense line and promotes the development of the industry in the direction of safety and compliance.