As the global poultry meat trade continues to grow, the quality and safety testing of exported poultry meat has become a "compulsory course" for enterprises to enter the international market. However, the cost investment in the testing process is often a major challenge for enterprises - from sample collection to laboratory testing to result review, each link may incur high labor, time and reagent consumption costs, especially when each batch of products needs to be fully tested, and the testing burden of small and medium-sized enterprises is significantly increased.

Traditional poultry meat testing relies on large-scale laboratory equipment, using cumbersome pretreatment processes and complex chemical analysis methods. Not only does the testing cycle take a long time (usually 24-48 hours or even longer), but also the cost of a single test is high. For export enterprises, if each batch of products needs to undergo strict full testing, it will not only take up a lot of funds for reagent procurement and equipment maintenance, but also may affect the delivery timeliness due to the long testing cycle, which may indirectly increase the time cost. In addition, some enterprises may over-repeat the test in order to ensure the safety of the test results, further pushing up the overall cost.

Colloidal Gold Card Pre-inspection Shunt: A New Idea to Crack the Cost Problem

Faced with this pain point, Colloidal Gold Card Technology has become an ideal choice for pre-inspection shunt due to its fast, convenient and low-cost characteristics. Colloidal Gold Card Detection is a rapid detection technology based on the principle of immunochromatography, which can complete the screening of specific indicators within 15-30 minutes, especially suitable for the initial detection of large-scale samples. Through the colloidal gold card for pre-inspection and shunting, the detection strategy of "screening first, then accuracy" can be realized: for samples with negative test results (or in line with standards), the follow-up detection process can be simplified, and unnecessary reagents and time investment can be reduced; for samples with positive test results (or suspected abnormalities), the high-precision detection method is used to verify, which not only ensures the rigor of quality control, but also greatly reduces the overall detection cost.

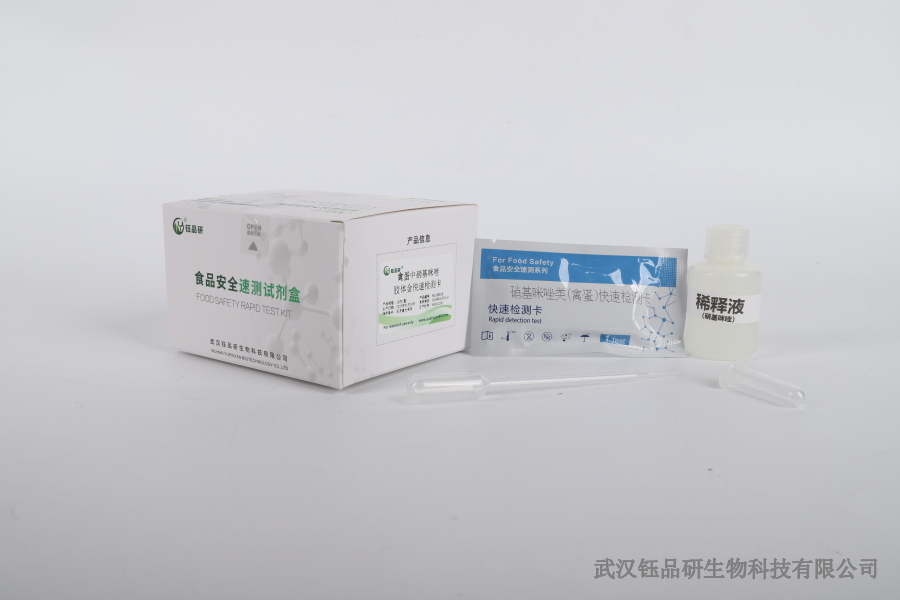

Wuhan Yupinyan Bio: Helping poultry meat detection to reduce costs efficiently

As an enterprise focusing on the research and development of food safety rapid detection reagents, Wuhan Yupinyan Bio knows the importance of testing costs to enterprises. The colloidal gold card detection reagent developed by the company relies on a stable antigen-antibody reaction system, which not only ensures the accuracy of detection, but also realizes the simplification of the operation process and the shortening of the detection time. Without the need for professional laboratory equipment and complex operation training, the testing personnel only need to complete the sample processing and test strip reading according to the instructions, and can quickly obtain preliminary results. This "rapid screening + accurate verification" model not only helps export poultry meat enterprises to greatly reduce the cost of single detection, but also improves production efficiency by shortening the detection cycle, becoming an effective tool to solve the problem of high cost of export poultry meat detection.

To sum up, the problem of high cost of export poultry meat detection can be effectively alleviated by the combination of colloidal gold card pre-detection and shunt technology and efficient and rapid detection reagent. We will continue to optimize the testing products, provide more economical and efficient solutions for enterprises, and help the export poultry industry find a balance between quality and safety and cost control.