In the food safety rapid detection work, the operation standardization of grass-roots inspectors directly affects the accuracy and reliability of the test results. Colloidal gold rapid detection card, as a commonly used detection tool, is widely used due to its advantages of simple operation and fast results. However, some grass-roots inspectors often have problems such as improper sample handling and inaccurate control of reaction time due to unskilled operation, resulting in deviations in test results and difficulty in meeting the refined requirements of food safety supervision. In order to solve this pain point, Wuhan Yupinyan Bio combined with the first-line detection needs to sort out the colloidal gold card standardization training tutorial to help grass-roots inspectors quickly master standardized operation methods and improve detection capabilities.

Necessity of Colloidal Gold Card Standardization Training

Colloidal gold card testing may seem simple, but in practice, every link may affect the final result. For example, if the sample extraction is not completely centrifuged, it may lead to impurities interfering with the detection; if the sample amount is insufficient or overflowed during the reaction, it will make the color development area uneven; if the interpretation exceeds the specified time, false positive or false negative results may occur. These irregular operations will not only waste testing resources, but also cause misjudgments and affect the accurate assessment of food safety risks. Through standardized training, inspectors can systematically learn the operation points, reduce human errors, ensure the consistency and credibility of the testing data, and provide solid data support for food safety supervision.

the standardized operation process of colloidal gold card testing

colloidal gold card testing needs to strictly follow the standardized process of "preparation-operation-interpretation-record", and each step has clear specifications.

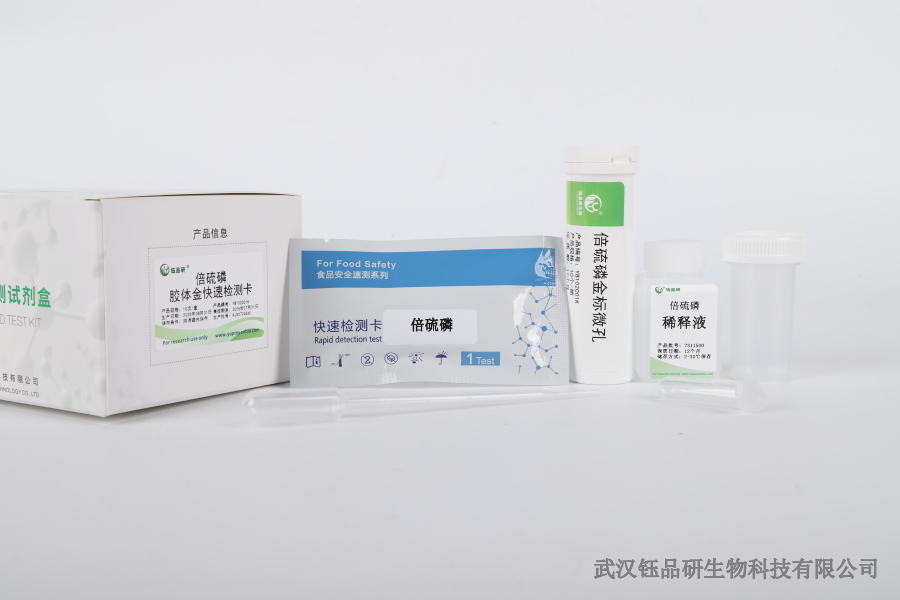

preparation before testing: first check whether the colloidal gold card is within the valid period, and the reagent card is stored in an environment of 2-8 ° C to avoid direct sunlight and high temperature. Prepare a clean sample container, pipette and timer before testing to ensure that there are no obvious sources of interference in the operation area. When processing the sample, if it is a liquid sample, it needs to be fully mixed and an appropriate amount is taken; if it is a solid sample, the extract should be added as required and shaken to extract, let stand for 5-10 minutes and then take the supernatant for later use. Operation

detection: Add the processed sample to the loading hole to ensure that the liquid level does not exceed the loading line, and wait 10-15 minutes (refer to the reagent manual for the specific time) to complete the immune reaction. Avoid shaking or touching the card during the reaction to prevent the liquid flow from causing abnormal color development.

Interpretation after detection: Within the specified time, if the quality control line (C line) has clear color development, the color development of the detection line (T line) is a negative result; if only the C line has color development, the T line does not develop color is a positive result; if the C line does not develop color, whether the T line has color or not is considered invalid and needs to be re-tested. When interpreting, it is necessary to observe under natural light or special light source to avoid misjudgment caused by color deviation.

result recording and processing: After the test is completed, record the test results, sample number and test time in time, and discard the reagent card according to the medical waste specification to avoid environmental pollution.

common operation problems and solutions

Grassroots inspectors often encounter the following problems in actual operation, which need to be solved in a targeted manner:

First, "liquid overflow after adding sample". The reason is mostly improper use of the pipette or too much sample. The solution is to choose a pipette with an appropriate range, and keep it vertically and slowly injected when adding sample to ensure that the liquid level does not exceed the upper limit of the sample hole.

second is "C-line light color or no color". It may be caused by expired reagents, insufficient reaction time or damp card body. It is necessary to check the valid period of the reagent, strictly control the reaction time, and keep the reagent dry and stored.

third is "T-line color blurred". Usually there are interfering substances in the sample or the extraction is not complete. It is recommended to purify the sample for a second time, or replace it with a new reagent card for re-detection.

By repeatedly practicing standardized operations and simulating common problems, the testing personnel can quickly improve their coping ability and reduce the operation error rate.

Wuhan Yupinyan Bio always pays attention to the actual needs of grass-roots inspectors, relies on professional R & D and production experience, and continuously optimizes the performance of detection reagents and supporting training programs. Standardized training can not only help inspectors master the operation of colloidal gold cards, but also improve the ability to respond quickly to food safety risks. In the future, we will continue to promote the popularization of detection technology and operating norms, and contribute to building a safer food safety defense line.