As an important source of high-quality protein in the daily diet, the safety and quality of poultry eggs are directly related to public health. In recent years, the illegal use of antibiotics (such as doxycycline, metronidazole, etc.) in the production of some poultry eggs has attracted attention. These drug residues may not only cause health risks such as human allergies and drug resistance, but also damage the reputation of the poultry egg industry. In this context, the rapid detection technology for poultry egg drug residues has become a key link in food safety supervision, and the targeted detection scheme for common residues such as doxycycline and metronidazole is gradually becoming the industry standard.

Traditional poultry egg drug residue detection relies on laboratory high-performance liquid chromatography (HPLC), gas chromatography-mass spectrometry (GC-MS/MS) and other technologies. Although the accuracy is high, there are problems such as time-consuming (hours to days), expensive equipment, and complicated operations, which are difficult to meet the needs of on-site rapid screening and large-scale supervision. The targeted fast inspection solution has achieved a double breakthrough of "speed + accuracy" by optimizing the detection process and technical means.

taking doxycycline detection as an example, the scheme adopts immunochromatography technology (colloidal gold labeling), through the principle of specific binding of antigens and antibodies, a clear detection line and quality control line are formed on the test strip. The results can be interpreted 10-15 minutes after the sample is added, and the detection limit can reach 0.1-1 ng/mL, which is far lower than the national standard limit. For nitroimidazole drugs such as metronidazole, the scheme combines molecular imprinting technology (MIP), using synthetic specific identification materials, high-efficiency capture of the target, and fluorescence quantitative PCR or Raman spectroscopy to achieve precise quantification at the pg level, with an error rate of less than 3%. The core advantage of

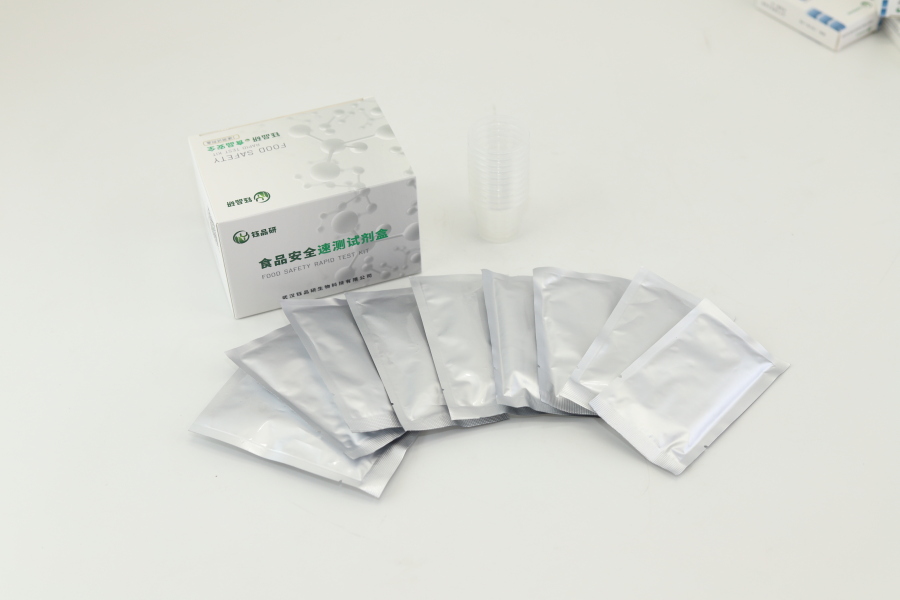

's targeted detection technology is "targeting" - that is, designing a dedicated detection probe for specific drug residues, avoiding sample matrix interference (such as fat, protein and other components in poultry eggs), and greatly improving the detection specificity and sensitivity. At the same time, the miniaturized design of the equipment allows the detection to be rapidly deployed in the field, wholesale market, production workshop and other scenes, without professional laboratory conditions, and can be operated by grass-roots supervisors and enterprise self-inspection personnel after simple training.

At present, the rapid inspection solution for poultry egg drug residues has been widely used in raw material acceptance of poultry egg production enterprises, wholesale market entry testing, and sampling inspection by regulatory departments. Through the targeted screening of common drug residues such as doxycycline and metronidazole, it can not only quickly identify illegal products, curb drug abuse from the source, but also provide consumers with "visible safety", and promote the development of the poultry and egg industry towards standardization and high quality. With the technological iteration, the future plan will also integrate AI image recognition, Internet of Things data upload and other functions to realize the intelligent supervision of the whole process of drug residue detection, and build a "technological barrier" for the food safety defense line.