As an important source of high-quality protein in the daily diet, the quality and safety of poultry eggs has always been the focus of consumers' attention. In recent years, with the popularity of pesticide use in agricultural production, the problem of pesticide residues in poultry eggs has gradually become prominent, which not only affects product quality, but also may pose a potential threat to human health. Traditional methods for detecting pesticide residues in poultry eggs rely on complex laboratory equipment and cumbersome processes, which often take days or even weeks to obtain results, making it difficult to meet the needs of the market for rapid screening and supervision. In this context, the rapid detection solution for pesticide residues in poultry eggs came into being. Through innovative technologies and optimized processes, a double breakthrough in detection efficiency and accuracy has been achieved, building a "rapid response network" for the safety defense line of poultry eggs. The core of the rapid detection solution for pesticide residues in

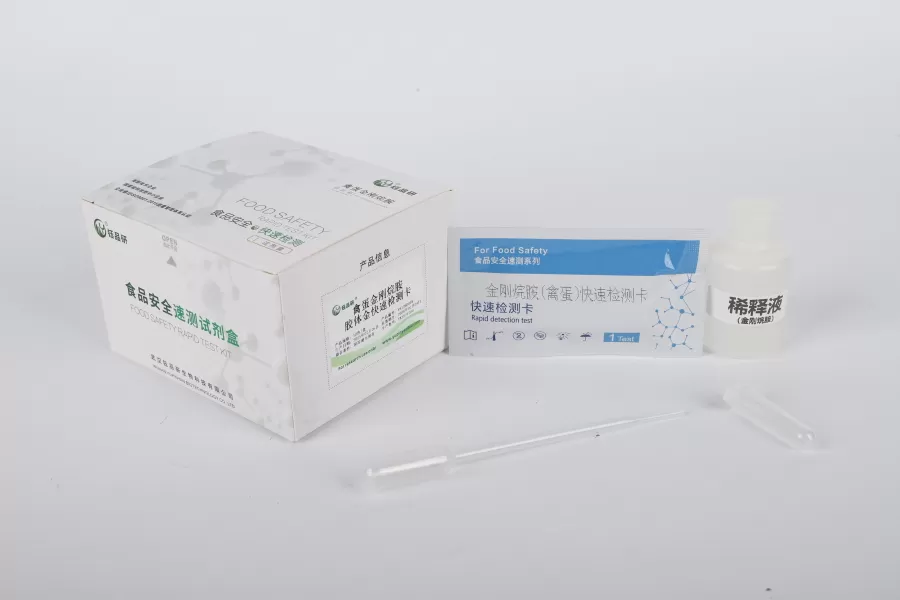

eggs lies in the balance of "fast" and "accurate". In traditional detection methods, sample pretreatment takes a long time and requires professional equipment and operators, while rapid detection technology greatly shortens the detection cycle by integrating cutting-edge means such as immunoassay, spectral identification, and biosensors. For example, the detection test paper based on colloidal gold immunochromatography technology requires only a small amount of samples (such as eggshell surface wiping liquid or egg yolk supernatant), and can complete the detection in 10-15 minutes. The pesticide residue can be judged by intuitive color rendering results, which is easy to operate and does not require complex instruments. In addition, enzyme inhibition rate method, Raman spectroscopy detection and other technologies have also been widely used in the field of rapid detection. Through the analysis of pesticide inhibitory enzyme activity or characteristic spectrum, the accurate identification of common pesticide residues such as organophosphorus and pyrethroid can be achieved. The detection sensitivity can reach the level of μg/kg, which fully meets the requirements of national standards.

This scheme not only has significant advantages in efficiency, but also shows strong practicality in practical applications. In poultry and egg production enterprises, rapid testing equipment can be used as the "first line of defense" to screen products in batches before leaving the factory, remove unqualified products in time, and reduce circulation risks; in agricultural wholesale markets and regulatory authorities, portable testing equipment can realize on-site sampling inspection, quickly lock in high-risk products, and reduce the probability of unqualified eggs entering the market; for e-commerce platforms and catering enterprises, rapid testing programs can provide consumers with "transparent" safety commitments and enhance market trust. At the same time, the program can also be combined with big data platforms to provide data support for pesticide use guidance and policy formulation at the agricultural production end by recording test data and analyzing the regional distribution and seasonal patterns of pesticide residues.

With the continuous iteration of technology, the rapid detection scheme for pesticide residues in poultry eggs is moving towards a more intelligent and miniaturized direction. The integration of the new detection chip is improved, and the detection time is further shortened to a few minutes; the introduction of AI image recognition technology can automatically analyze the detection results and reduce manual errors; real-time monitoring equipment in cold chain logistics can realize the residue risk monitoring of the whole chain of poultry eggs. These innovations not only improve the detection efficiency, but also lower the technical threshold, so that grass-roots inspectors and small enterprises can easily master it.

The promotion and application of the rapid detection scheme for pesticide residues in poultry eggs is an important manifestation of the modernization of the food safety management system. It responds to "latent risk" with "rapid response", guarantees "table safety" with "accurate screening", and provides strong support for protecting consumers' "health on the tip of the tongue". In the future, with the continuous breakthrough of technology and the continuous reduction of costs, the program will play a greater role in the quality control, market supervision, and consumer trust building of the poultry and egg industry, and promote the development of the poultry and egg industry in a safer and more standardized direction.