With the continuous improvement of standardized requirements for pesticide use in agricultural production, rice, as one of the main food crops in our country, often uses pesticides such as triazophos to control pests and diseases during the planting process. However, if the amount of pesticides used exceeds the standard or the harvest interval after application is insufficient, it may lead to excessive triazophos residues in rice, which affects food safety and consumer health. When the detection finds that the triazophos residues in rice exceed the standard, scientific and effective treatment measures should be taken in time to reduce the risk from the source.

Residue reduction treatment: the key steps to scientifically reduce triazophos residues

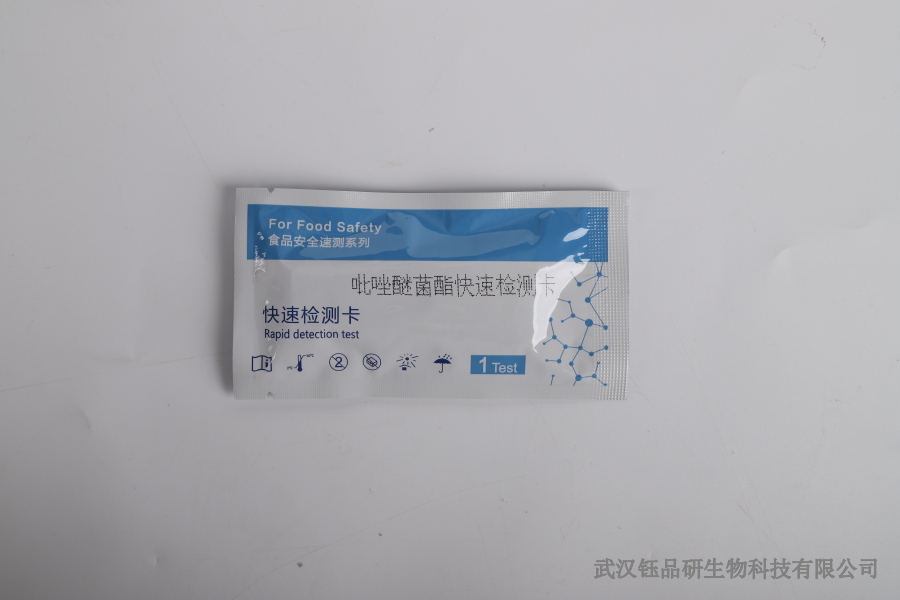

For rice with excessive triazophos residues, the residue reduction treatment needs to combine physical, biological and process optimization methods, and at the same time use professional detection tools to monitor the effect in real time. First, the physical removal method can be used to remove residual pesticides in the surface layer and part of the endosperm through multiple soaking, rinsing or moderate milling; secondly, biodegradation technology is also more effective in practical applications, such as using microbial preparations that meet standards to treat rice for a short time to accelerate the decomposition of pesticides; in addition, adjusting the processing technology can also reduce residues, such as finely screening the rice beyond the standard to separate the high-quality parts with low residues. During the entire residue reduction process, the food safety rapid detection reagent developed by Wuhan Yupinyan Bio can play a key role. Through test strips or rapid detection instruments, it can complete the qualitative or semi-quantitative detection of triazophos residues in rice samples in a short time, helping enterprises to accurately grasp the treatment effect and ensure that the treated rice residues meet safety standards.

Disposal of non-conforming products: Standardized process and safety control

For the detection and confirmation of rice residues exceeding the standard, it is necessary to strictly implement the disposal process of non-conforming products to avoid flowing into the food supply chain. First, the unqualified rice is physically isolated and stored, and a special area is set up and marked to prevent confusion with qualified products. Second, the degree and scope of exceeding the standard are further confirmed through laboratory accurate testing (such as quantitative analysis using national standard methods) to determine whether there is a risk of secondary pollution. Then, according to the test results, the treatment is graded: if the excess amount is low and can be reduced to a safe value through secondary processing, the above-mentioned residue reduction treatment methods can be used for re-testing; if the excess standard is serious and cannot be met through treatment, it is necessary to follow the requirements of food safety laws and regulations, and take destruction or professional harmless treatment. It is strictly forbidden to use it directly as a food raw material. In the process of disposal, the enterprise needs to establish a complete ledger record, including test data, treatment measures, responsible person and other information, to ensure that the flow of each batch of non-conforming products can be traced, and at the same time, the disposal process is regularly evaluated and optimized to reduce the risk of excessive triazophos residues from the root cause.

Faced with the problem of excessive triazophos residues in rice, scientific treatment is an important link to ensure food safety. Through the systematic process of residue reduction treatment and standardized disposal of non-conforming products, combined with the precise monitoring support of Wuhan Yupinyan biological rapid detection reagents, enterprises can effectively control risks and provide consumers with safe and reliable food products. In agricultural production and grain processing, attention should be paid to testing and scientific disposal in order to fundamentally build a strong food safety defense line.