In food safety testing, triazophos, as an organophosphorus insecticide, is often used for crop pest control. However, if triazophos residues in agricultural products exceed the standard, it may pose a potential threat to human health. When triazophos is found to exceed the standard through testing, scientific measures need to be taken in a timely manner, and every step from the result determination to subsequent disposal cannot be ignored.

test result determination: preliminary screening and confirmation

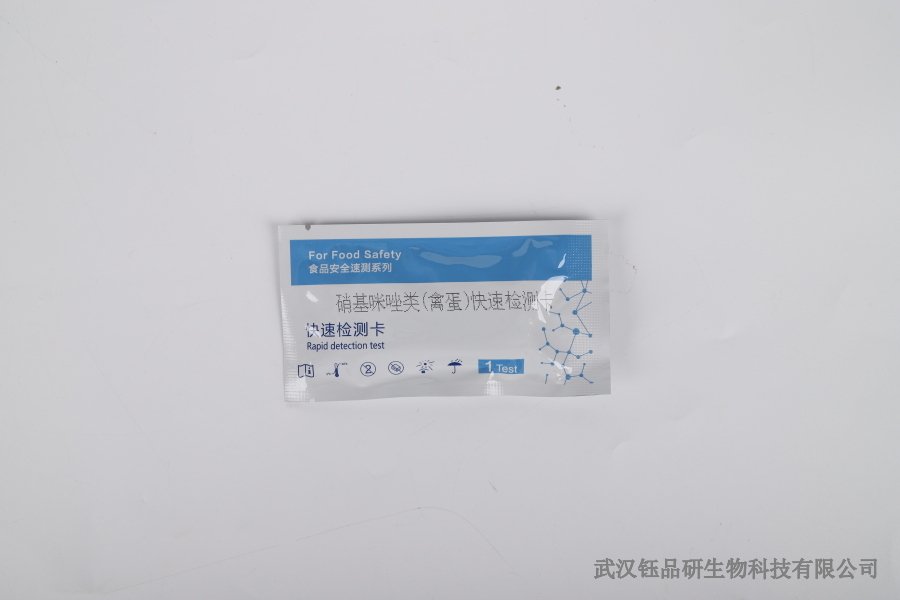

test result determination needs to be combined with preliminary screening and confirmation. First, professional food safety rapid detection reagents should be used for preliminary judgment, such as the food safety rapid detection reagent produced by our company, which is easy to operate and highly sensitive, and can conduct preliminary screening of triazophos residues in samples in a short time. If the test result is positive, it needs to be further verified by laboratory confirmation methods (such as gas chromatography-mass spectrometry and other national standard methods) to avoid false positives or false negatives caused by rapid testing. At the same time, attention should be paid to environmental control during the detection process to ensure that sampling, pretreatment, reagent reaction and other links meet the standards to ensure the accuracy of the results.

Follow-up treatment process: Standardize operation and risk control

When triazophos exceed the standard, the follow-up treatment process needs to be started immediately. The specific steps are as follows: First, stop selling or using relevant batches of products, and fully seal the problem products in stock and circulation to prevent them from continuing to flow into the market or causing secondary pollution. Secondly, report the situation to the local agricultural and rural departments and market supervision and management departments in a timely manner, cooperate with the investigation and evidence collection, and provide complete test data and relevant records, so that the regulatory department can evaluate the nature and impact scope of the incident. At the same time, it is necessary to recall the problem product, notify the relevant units or consumers through the original sales channels to return it voluntarily, and do a good job of recycling registration. Finally, the enterprise needs to investigate the reasons in depth, which may involve problems such as irregular drug use in planting and breeding, improper transportation and storage, and optimize the management process in a targeted manner. Strengthen the quality control of raw materials and auxiliary materials to ensure the safety and control of subsequent products.

summary: early prevention and continuous improvement

It is worth noting that food safety is no small matter. The disposal of triazophos exceeding the standard is not only responsible to consumers, but also the basic requirement of the enterprise's own compliance management. In daily production and operation, the source control should be strengthened, the compliance pesticide products should be selected, the use specifications should be strictly adhered to, and the self-inspection work should be carried out regularly. With the help of rapid detection reagents, the latent risk should be found in advance to solve the problem in the embryonic stage. Only through scientific testing and standardized disposal can we effectively ensure food safety, maintain public health and market order.